StormFilter®

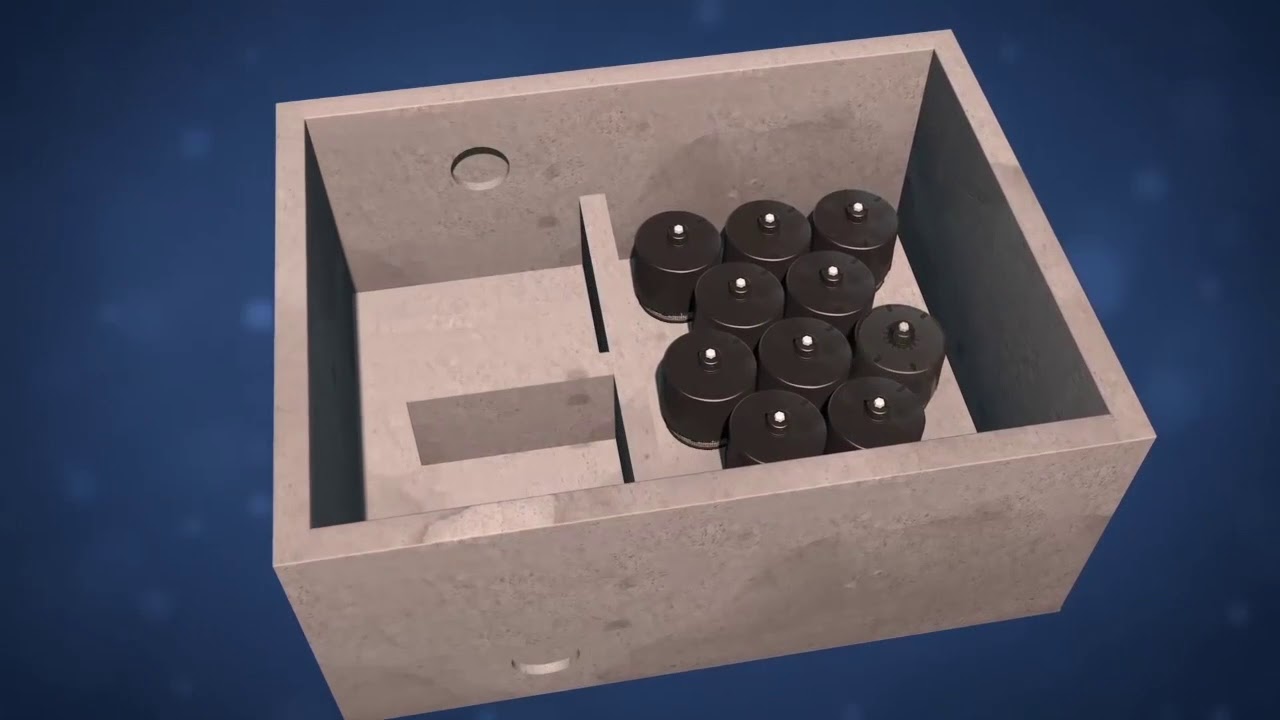

The Stormwater Management StormFilter® cleans stormwater through a patented passive filtration system using rechargeable, self-cleaning, media-filled cartridges to absorb and retain pollution in a compact underground system.

The StormFilter® stormwater treatment system uses rechargeable, self-cleaning, media-filled cartridges to absorb and retain the most challenging pollutants from stormwater runoff including total suspended solids, hydrocarbons, nutrients, soluble heavy metals, and other common pollutants.

The siphon actuated, high surface area cartridges draw stormwater evenly through the filter media, providing efficient, effective stormwater treatment. The self-cleaning hood prevents surface blinding ensuring maximum media contact, prolonging cartridge life.

The StormFilter® is available in multiple cartridge heights to meet site-specific hydraulic needs and is available in different configurations. The unique design provides prolonged maintenance periods to ensure long-term performance and reduced operating costs.

For more than two decades, StormFilter® has helped clients meet their regulatory needs and through product enhancements the design continues to be refined for ease of use.

How the StormFilter Treats Stormwater

- During a storm, runoff passes through the filtration media and starts filling the cartridge centre tube. The air inside the hood is purged through a one-way check valve as the water rises

- When water reaches the top of the float, buoyant forces pull the float free and allow filtered water to exit the cartridge. A siphon is established within each cartridge that draws water uniformly across the full height of the media bed ensuring even distribution of pollutants and prolonged media longevity

- After the storm, the water level in the structure starts falling. A hanging water column remains under the cartridge hood until the water level reaches the scrubbing regulators at the bottom of the hood

- Air then rushes through the regulators, breaking the siphon and creating air bubbles that agitate the surface of the filter media, causing accumulated sediment to settle on the treatment bay floor. This unique surface-cleaning mechanism prevents surface blinding and further extends cartridge life

Features

- Siphon actuated, high surface area media cartridges

- Multiple cartridge heights

- Multiple media options

- Multiple configurations

- Maintenance intervals of one to five years

Benefits

- Stormwater is drawn evenly through the filter media providing efficient, effective stormwater treatment

- Flexibility in arrangement and hydraulics to meet your sites needs

- Target specific pollutants including TSS, nutrients, heavy metals and hydrocarbons

- Lightweight, reusable cartridges

- Fewer maintenance events and reduced long-term ownership costs

Configurations and Applications

- Commercial, Industrial and Residential development, infill and redevelopment and stormwater quality retrofit applications

- Special projects: Highways, airports, seaports and military installations

- Pre-treatment for Water Sensitive Urban Design (WSUD), infiltration and rainwater harvesting and reuse systems

Maintenance

- Reduce Life Cycle Costs – The cartridge design and re-usable housing result in a reduced life-cycle cost, when compared with other filtration technologies

- Easy to maintain – Visual indicators for maintenance are observable from the surface and direct access for inspection, media replacement and washing of the structure is incorporated into system design

- Cartridge exchange – Ocean Protect supplies refurbished cartridges with fresh media. These are exchanged with the empty cartridges from site, reducing both the ongoing maintenance costs and environmental impact